Remanufacturing CS-400E Cut & Clinch Machine

STEP 3: Rebuild Subassemblies

3.1 Cut and Clinch Mechanism

The crux of the CS-400E machine is the cut and clinch mechanism.

All remanufactured machines will have totally rebuilt cut and clinch units.

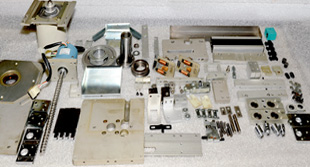

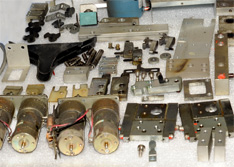

Disassembling |

|

|

|

|

The mechanism is completely disassembled, cleaned, and lubricated. Worn parts including motors, cutter, and the like are replaced with new parts. |

|

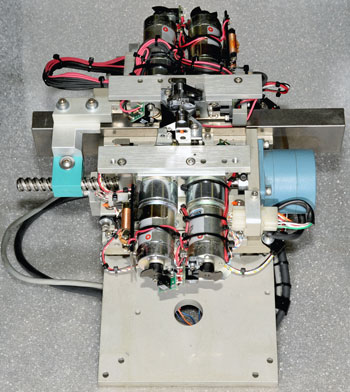

Remanufactured cut and clinch mechanism.

The cut and clinch mechanism is reassembled to factory specifications. |

|